ZERO-I PLUS Coating

(pronounced “Zero-One Plus”)

- ZERO-I PLUS Coating

-

This coating maintains the same film thickness

as ZERO-I while delivering superior smoothness

and anti-adhesion performance.

Instead of relying solely on film hardness for

wear resistance, it achieves long-term stability

through a controlled, gradual wear process.

Suitable for various applications including cold

forging, galvanized steel sheets, and stainless steel

processing.

ZERO-I PLUS Coating is recommended in this field

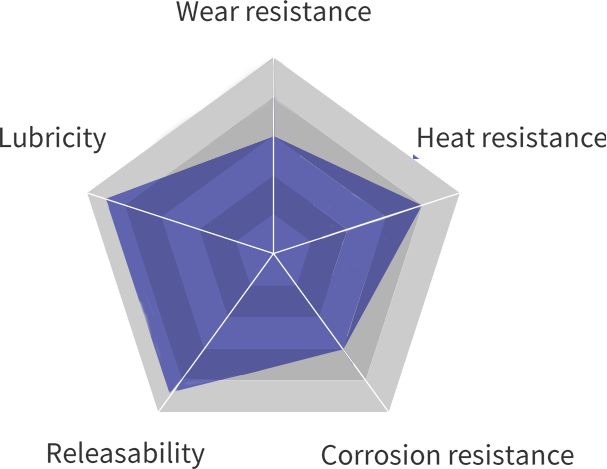

Feature

- Lubricity and Anti-Adhesion

By optimizing the film hardness to reduce shear force, this coating minimizes surface drag and deformation resistance. It provides excellent sliding performance against counterpart materials, effectively preventing adhesion and galling wear. Additionally, it helps suppress surface scratches on the counterpart material.

- Stability

By optimizing the balance between film hardness and the coefficient of friction, the coating promotes gradual, controlled wear, preventing sudden cracking or delamination of the film.

- Film hardness::Hv2,500

- Heat-resistant temperature:700℃

- Coefficient of friction:0.40

- Operating temperature:500℃

- Recommended film thickness:4 - 6μm

- Related products