ZEROⅠcoating

- ZEROⅠcoating

-

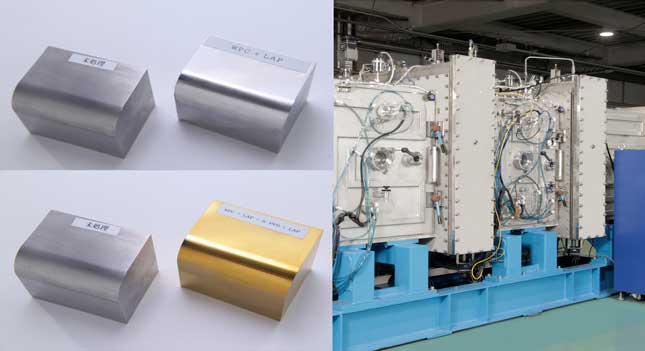

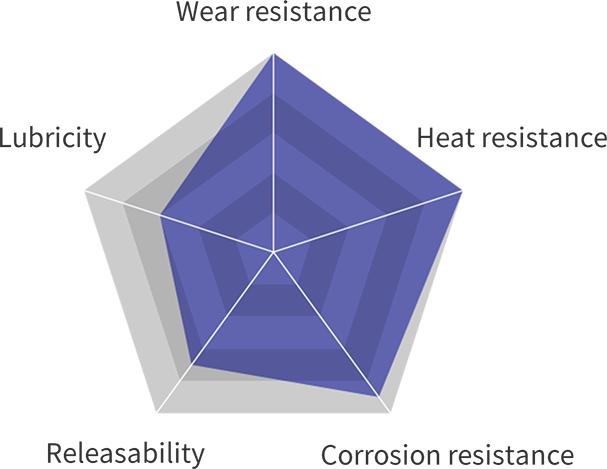

Developed newly ZERO-I ( Zero One) coating from the existing PVD Coating for higher hardness, heat resistance and lubricity . Superior wear resistance contributes to longer life.

Abrasion resistance, heat resistance improvement, cold press, cold forging, warm forging, punching die high-tensile press molding, FB molding, etc.

ZEROⅠcoating is recommended in this field

Feature

- High hardness

Automobile industry, the use of molds under severe conditions such as high-tensile steel and thickening has progressed, and it has become a challenge to suppress local elastic deformation that induces film peeling. ZERO-Ⅰcleared those problems and also surpass Hv 3,500 over TiCN/TiALN has achieved high hardness.

- High heat resistance

Achieves 1,000 ℃ exceeding TiAlN .

Corresponding to frictional heat oxidation and warm forging in cold forging, which causes of seizure.

- High adhesion thick film

Mostly, PVD film thickness is 2~3µm, but ZERO-I has allowed both high adhesion and thick film by the stress relaxation techniques. This improves wear resistance and increases the effect of suppressing elastic deformation.

- Film hardness: Hv3,500

- Heat-resistant temperature: 1,000℃

- Coefficient of friction: 0.60

- Operating temperature: 500℃

- Recommended film thickness: 4µm more

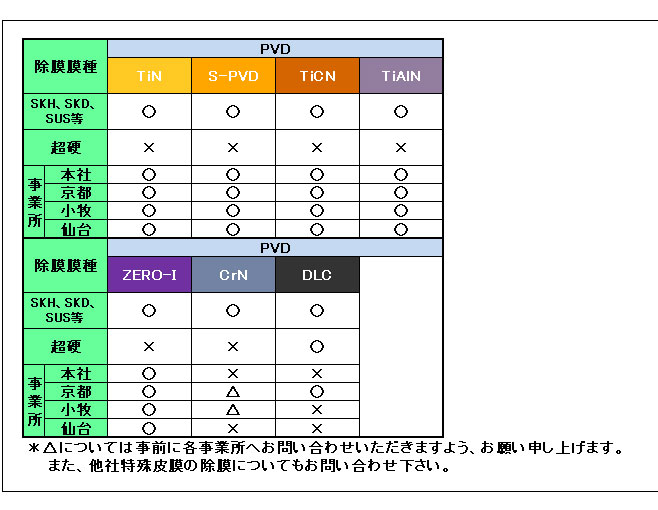

- Related products