-

01

Technical capabilities

-

02

Manufacturing capabilities

-

03

Proposal capabilities

-

04

System development

-

05

Human Resources Power

01. Technical capabilitiesManufacturing experience with over hundred of customers

Our company owns manufacturing department and contract-based process department, and we have accumulated consistent hardware and software know-how from device manufacturing to contract-based process. Because of this business type provides quick feedback on the feeling of use and encourages improvement activities. These activities make it possible to meet various customer demands, and have accumulated manufacturing experience with over hundred of customers. This is a reason, which customer will choose SEAVAC.

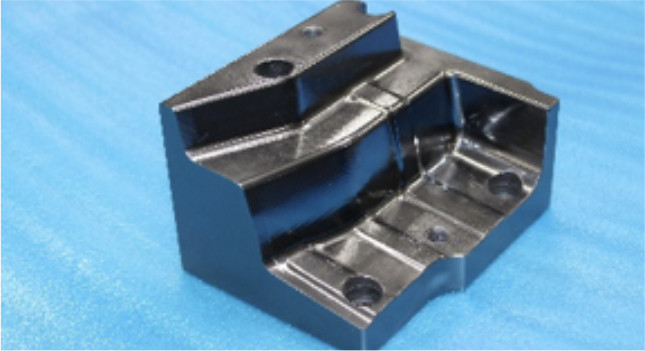

Surface treatment and improved properties

Surface treatment is a treatment that adds different properties to the material surface by heat treatment or vapor deposition. By adding these different properties like, wear resistance, corrosion resistance, oxidation resistance, slidability, water repellency, etc. that could not be demonstrated with the material alone can be improved.

For molds that produce automotive parts, surface treatment improves the lifespan , improving productivity, reducing mold costs, and engine parts contributing to improve fuel efficiency, and ecology by reducing friction.

The main customer is an auto parts manufacturer, but we have received drawings from our auto makers, and we have a wide range of achievements such as other weak electrical parts makers and medical parts makers.

Device introduction

-

Inline device

AIP-IV65 -

UBMS device

UBMS-504 -

PAIC device

PAIC-600

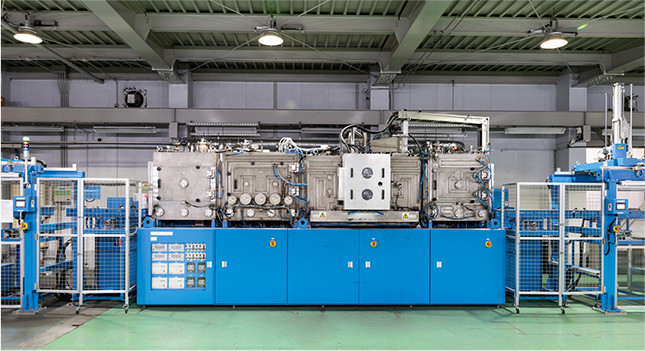

02. Manufacturing capabilitiesManufacture and sales of coating device, development of new fields

Manufacturing depertoment transitions include heat treatment furnace manufacturing and sales (End),contract-based heat treatment process, CVD coating contract processing (end), PVD coating contract processing, PVD coating device manufacturing and sales, system sales, and we are also working on development further into new fields.

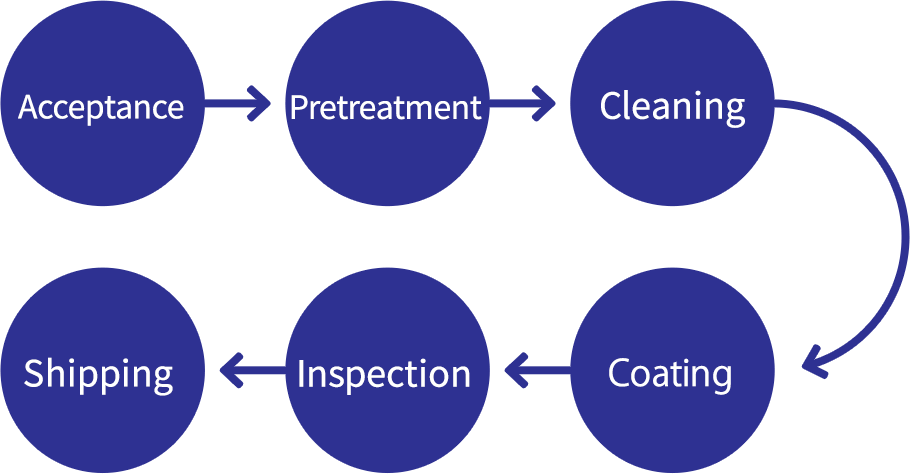

Flow of contract coating processing

We received products and check the requirements from customers.In the case of heat treatment, the furnace and conditions are selected according to the material type and specified hardness. After heat treatment process, pass or fail is judged by hardness measurement and furnace operation.

In the case of PVD coating, after confirming the surface condition suitable for coating, the surface is improved if necessary, and the cleaning process and PVD coating are performed. After that, we will check the appearance, the operation of the processing furnace, the film thickness, adhesion of the test piece, and pass or fail Judgment before shipping.

-

Mold

cold forging, warm /hot forging, press, injection molding, weak electric, medical, die casting

-

Cutting tool

end mill, drill, tap, reamer, hob cutter, metal saw, etc.

-

Cold tool

automobile, light electric, medical

● cold forging, warm /hot forging, press, injection molding, weak electric, medical, die casting

● end mill, drill, tap, reamer, hob cutter, metal saw, etc.

● automobile, light electric, medical

03. Proposal capabilitiesIndustry leader in PVD coating market size

Our technology, which is positioned at the top of the PVD coating market scale, is characterized by mold and cutting tool makers who make shapes (materials), and heat treatment and PVD coating are contracted to provide the best products for customers. Therefore, we can make optimal proposals based on our experience and knowledge of heat treatment, CVD coating, and PVD coating among many achievements . In addition, we have the know-how that we can keep the product after using, confirming the situation, and making a suggestion again.

Select coating type

The differences in PVD coating types is the elements. Different elements have different properties. It varies depending on the element, such as strong against abrasion, good sliding property, and rust resistance. Again, if the mechanism for film formation changes, the properties change even if they are composed of the same elements.

Proposal capabilities of SEAVAC

We optimize proposals based on our experience and knowledge of heat treatment, CVD coating, and PVD coating among many achievements. In Addition, we have the know-how that we can keep the product after using, confirming the situation, and making a suggestion again.

Position in the industry

Our business format is that mold and cutting tool makers create shapes (materials), and then process heat treatment and PVD coatings on contract. We are positioned one of the leading company for PVD coating industly market scale.

04. Development capabilities of systemSEAVAC rapidly improve our systems, cause of set up In-house development

An integrated system for ordering, process management, quality records, and sales management specialized in the hard coating industry, as well as device manufacturing management, regular equipment maintenance, nonconformity, complaints, corrective action records, device error reports, internal audits, sales reports, purchasing management, proposals/settlement are developed in-house.Therefore, our development strength that can quickly improve the system according to the demands of in-house system users.Also, we have strengths that cover the hardware configuration and security measures from PC set up to server installation /configuration and network building. In addition, we offer services that customers can place an order by using our website (Our Original System).

05.Human Resources PowerSEAVAC heats surface and heart

One Layer that must be

We help and cooperate with all stakeholders on the idea of "Collaboration Advancement".

We value the spirit of challenge and enthusiastically work on the development and improvement activities of new technologies.

The accumulation of the power of every employee has created our only one technology.

SEAVAC forms high layers

We are actively engaged in research and development based on our corporate philosophy of "Collaboration Advancement": Technology

Inspiring by senior colleague who work gently and passionately: Manufacturing

Utilizing our processing experience and knowledge, we aim to be a reliable sales officer: Sales

Work in ways you likes, such as improving work efficiency and dispatch events: General Affairs

Growing up in SEAVAC

With a variety of training systems centered on OJT, we support the improvement of individual skills and the spirit of challenge.

We aim to create best working condition which all employees can continue to work with peace of mind by enhancing welfare programs inside and also outside the company.