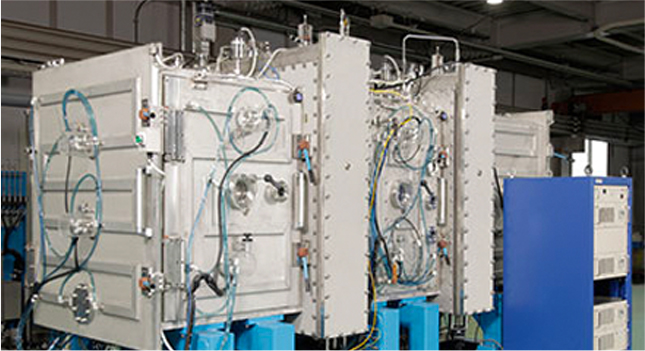

Base reinforcement (option)

- Base reinforcement (option)

-

Complex processing technology

In general, CVD is “bonding” by chemical reaction, whereas PVD is “evaporation” by collision energy, so the adhesion is generally inferior.

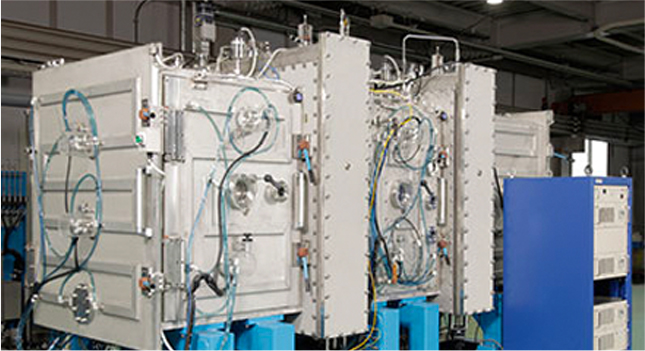

In order to improve the adhesion of PVD, it is effective to reduce the difference of hardness between the base material surface and the coating film. The difference is expanded especially with the increasing hardness of PVD. Therefore, SEAVAC adapted following technology as the base reinforcement.Base reinforcement (option) is recommended in this field

- WPC+PVD (Charged option)

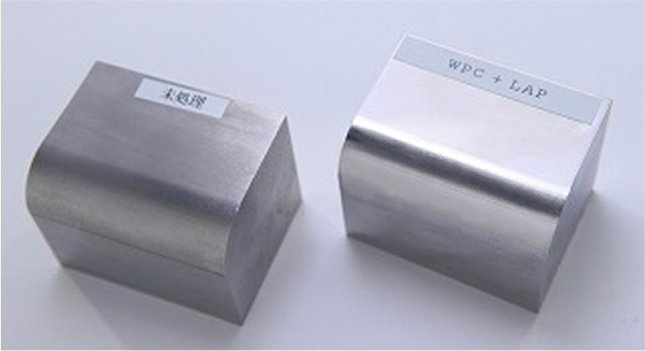

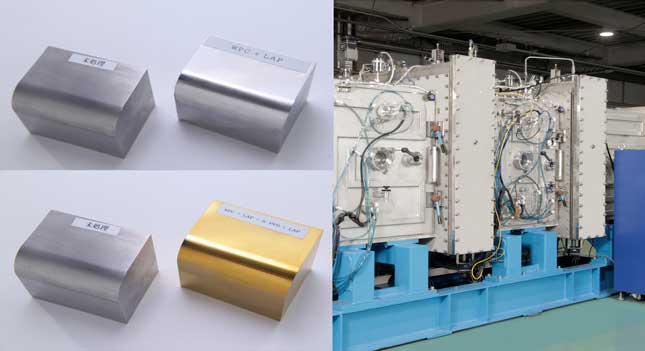

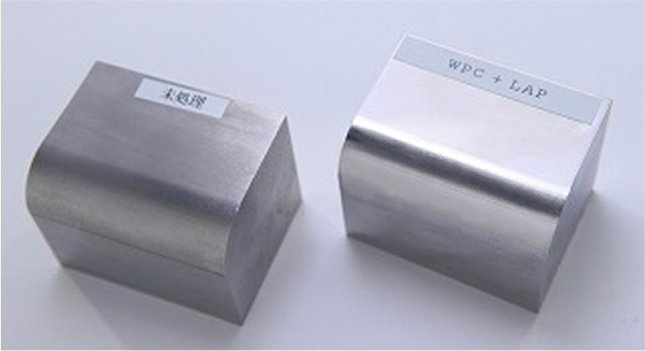

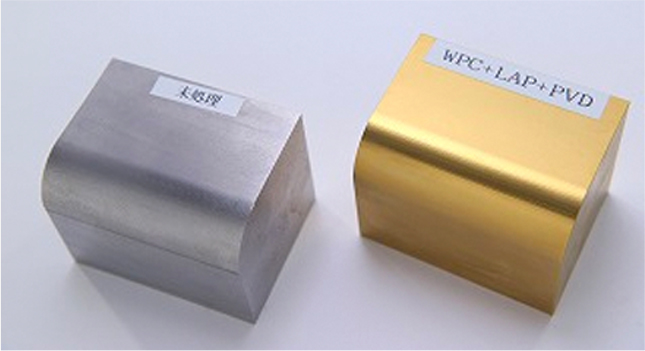

Left…Untreated Right…WPC+LAP

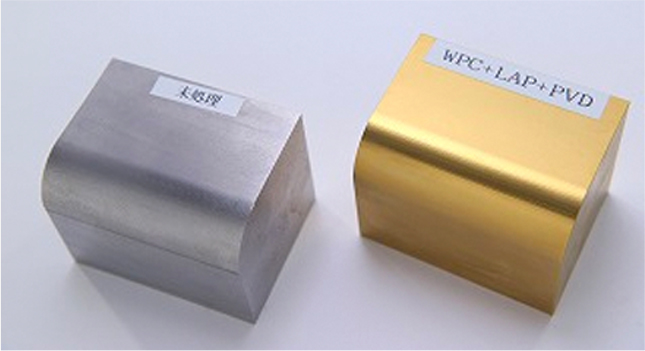

Left…Untreated Right…WPC+LAP+S-PVD Caused by colliding special fine particles such as HSS & ceramic on the surface, the hardness of the outermost surface will improve approx. 1.5 times.

A surface heat treatment effect can be obtained by impacting by shot blasting on a special surface equivalent to or better than a metal mold such as high speed steel or ceramic, and by rapidly repeat heating/cooling above the A3 transformation point.The outermost layer depth of about 10µm hardness improves up to approx. 1.5times from original layer. Caused by hardening the deposited surface of the coating, it is possible to improve adhesion, and only the surface is cured, so the toughness characteristics of the base material are maintained. In WPC processing, shot blasting forms a recess on the surface and the gloss is lost. PVD treatment is performed in our company after returning to the original glossy surface by lapping.

- Nitriding+PVD(Charged option)

Depth of about 30µm from the surface of the mold harden, nitride layer is the most hardest, it gradually becomes that inclined to return to the base material hardness as deeper. It is possible to perform very good nitridation on the outermost surface in our company, which is unlikely to generate a compound layer that adversely affects the adhesion with the coating called white layer.