ZERO-I W Coating

(pronounced “Zero-One Double”)

- ZERO-I W Coating

-

By doubling the film thickness of ZERO-I, this

coating provides significantly improved wear

and heat resistance.

Applications include cold stamping, hot

stamping, ultra-high tensile steel forming,

cold/warm/hot forging, and die-casting molds.

ZERO-I W Coating is recommended in this field

Feature

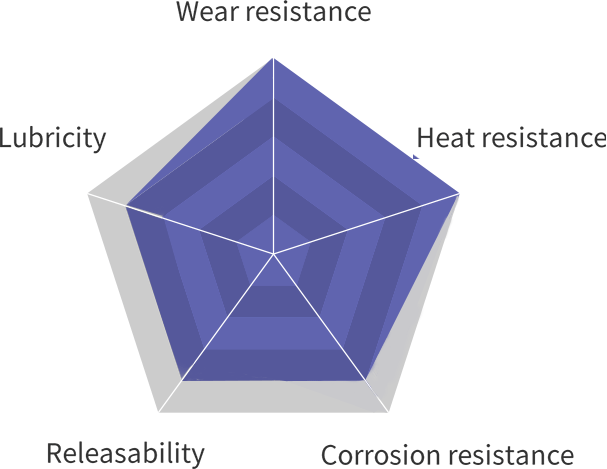

- Excellent Wear Resistance and Strong Adhesion

The increased film thickness further enhances wear resistance while maintaining exceptional adhesion to the substrate.

- High Heat Resistance

The thicker film helps reduce thermal impact on the base material. It resists oxidation and wear even under high-temperature conditions, making it suitable for processes prone to galling or seizure, such as warm and hot forging or die-casting operations.

- High Surface Pressure Resistance

The coating maintains stable performance even under high surface pressure environments.

- Film hardness::Hv2,500

- Heat-resistant temperature:700℃

- Coefficient of friction:0.40

- Operating temperature:500℃

- Recommended film thickness:4 - 6μm

- Related products